How To Calculate Man Hours For Production Excel Template

1. Partial factor productivity

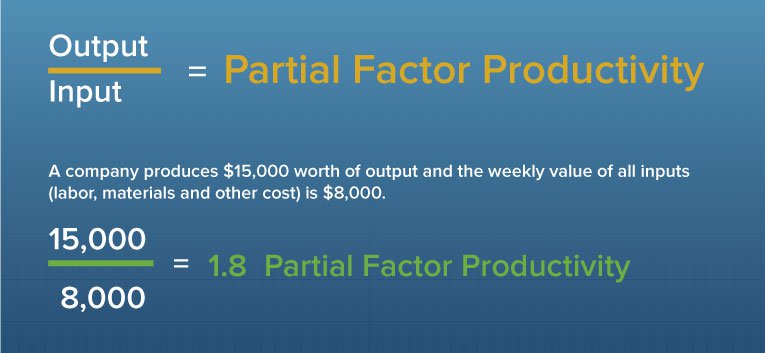

This formula is made up of the ratio of total output to a single input. Managers tend to use this formula most often because the data is available and easy to access. Also, partial factor productivity equations are easier to relate to specific processes because they only deal with one input.

To calculate partial factor productivity, let's say that a company produces $15,000 worth of output and the weekly value of all inputs (labor, materials, and other costs) is $8,000. You would divide 15,000 by 8,000, calculating a partial factor productivity of 1.8.

2. Multifactor productivity

Whereas the partial factor productivity formula uses one single input, the multifactor productivity formula is the ratio of total outputs to a subset of inputs. For example, an equation could measure the ratio of output to labor, materials, and capital. This method is a more comprehensive measure than partial factor productivity, but it's also harder to calculate.

We've asked Dan Keto, a productivity expert from Easy Metrics, to provide an example to illustrate one possible multifactor productivity equation.

One of our clients manages cross-docking operations for one of the nation's largest retailers. Cross-docking is where you take imported containerized ocean freight, unload it, then reload it into outbound truck freight. It is basically like taking apart a Rubik's cube and then reassembling it. The industry paradigm is to look at the production metric for the workers handling the freight in terms of cases per hour (CPH). Over a longer period of time, this is a reasonable metric. However, to manage operations daily per employee, it is not effective.

Each freight container can have from 40 cases to 20,000 cases on it depending on the type of product on the container and have as many as 100 different SKUs. The freight mix has a dramatic impact on the time it takes to process the work. Depending on the container mix, CPH can vary from 20 cases per labor hour to over 400.

Using CPH, the client was unable to have any consistency in either its productivity or labor forecast requirements because they were not using other factors present in the data to more accurately calculate the labor standard. By incorporating SKUs, splits, case weight and cube into the calculations, we were able to develop a multi-factor labor standard that could accurately and consistently predict the amount of labor required for each container of freight.

Using a linear regression model, the standard formula for this method is

HOURS = AX + BY + CZ + D

In the case of the above example, HOURS = A*(# Cases) + B*(Splits) + C*(SKUs) + D*(Cube) + E*(Weight) + F. The coefficients A-F are the calculated weighting factors multiplied against the input to get you the end result. These coefficients can be either calculated using time in motion studies (industrial engineering model) or if you have a large enough data set, linear regression tools. Modern technology and big data can now give even small operations the ability to calculate cost effectively multi-factor productivity standards.

The end result using the above example was that the client was able to see down to each employee what the productivity level was and then proactively manage and train accordingly. Labor costs were reduced by over 30%.

3. Total factor productivity

This formula combines the effects of all the resources used in the production of goods and services (labor, capital, material, etc.) and divides it into the output. This method can reflect simultaneous changes in outputs and inputs, however they do not show the interaction between each output and input separately (meaning they are too broad to be improve specific areas).

Once again, this equation is hard to calculate. Our productivity expert from Easy Metrics, a labor management system, shares an example to illustrate one possible calculation.

Measuring total factor productivity is both art and science. The key thing to keep in mind when building out this productivity metric is to focus on inputs that have a reasonable correlation for cost and efficiency to the output. Engineers will often want to measure every possible input factor around a process. Using big data analysis, we have often found that the correlation of many of these input factors is below the natural variance (noise) that occurs within the process, so collecting that information is often not worth the cost of doing so.

One of our customers is a large food processor that produces packaged vegetable products. They have roughly 200 employees per shift, working 16 equipment driven production lines and approximately 1000 different product SKUs. Their standard metric was to look at lbs per labor hour produced to measure their efficiencies, however this can be very misleading because depending on what the product is, there is a high variance between each product.

We worked with them to increase the number of factors measured to get a clear understanding of overall productivity as well as identify areas to focus on that can drive higher productivity. These factors were:

- Machine uptime: Measured as a percentage of shift hours

- Missing time: Variance between worker time clock time and time on production line

- Labor standard versus lbs/hr: Developed multivariate production standards based on pack style and commodity type/mix. Result scored as a percentage of standard where 100% means operating at expected productivity level.

- Product yield/loss: Qualitative factor that measured output weight versus input weight

- Input product quality factor: Commodity quality variances create variances in productivity

- Production run factor: Takes into account time to switch lines over to new product types. Short runs proportionately have comparatively larger set-up times per pound produce.

The end result was a comprehensive reporting dashboard with one macro result of the total productivity factor, scored as a percentage where 100% is daily goal, then each above sub-factor broken down so they could identify deficiencies. Each sub-factor is weighted in proportion to its importance. Labor standards and machine uptime were give weightings of each 30% with the other factors weighted less since those two factors were the primary driver of productivity.

Total Productivity Factor = 0.30 × Machine Uptime + .10 × Missing Time + .30 × Labor Standard + .10 × Product Yield + .10 × Input Quality Factor + .10 × Production Run Factor

The client now has clear visibility into their operations and the information at hand to address deficiencies as they arise.

How To Calculate Man Hours For Production Excel Template

Source: https://www.smartsheet.com/blog/how-calculate-productivity-all-levels-organization-employee-and-software

Posted by: sheavoiled.blogspot.com

0 Response to "How To Calculate Man Hours For Production Excel Template"

Post a Comment